Introduction:

In the world of high-performance vehicles, every ounce counts. The quest for speed, agility, and unparalleled performance drives enthusiasts to seek ways to optimize their machines. From shedding excess weight to enhancing thermal management, every modification can make a significant difference. In this comprehensive guide, we delve into the art and science of transforming your car or truck into a lean, mean driving machine.

The Weight Reduction Revolution:

Shedding Pounds for Speed: Understanding the Importance of Weight Reduction

Weight reduction is a cornerstone of high-performance vehicle modification. It’s not just about shedding a few pounds for cosmetic reasons; every ounce trimmed translates directly into improved acceleration, handling, and braking performance. By reducing the mass that the engine, suspension, and brakes must propel and control, drivers can achieve faster lap times, sharper cornering, and more responsive braking.

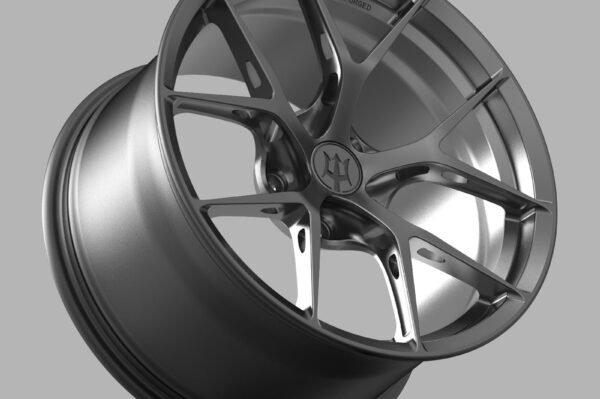

Forged Aluminum Wheels: The Lightweight Revolution

Forged aluminum wheels represent a significant advancement in automotive wheel technology. Unlike traditional cast wheels, which are made by pouring molten metal into a mold, forged wheels are created by applying extreme pressure to a solid billet of aluminum, shaping it into the desired wheel design. This process results in a wheel that is not only lighter but also stronger and more durable than its cast counterparts. The reduced unsprung weight of forged aluminum wheels improves suspension response, allowing the tires to maintain better contact with the road surface for enhanced grip and handling.

Exploring the Benefits of Forged Carbon Fiber Wheels

Forged carbon fiber wheels represent the pinnacle of lightweight wheel technology. Carbon fiber’s exceptional strength-to-weight ratio makes it an ideal material for high-performance applications, including automotive wheels. By using advanced manufacturing techniques such as autoclave molding, manufacturers can produce wheels with intricate designs and unparalleled strength. The result is a wheel that is significantly lighter than traditional aluminum or steel wheels, yet capable of withstanding the rigors of high-speed driving. The reduced rotational mass of carbon fiber wheels improves acceleration, braking, and cornering performance, making them a popular choice among performance enthusiasts and professional racers alike.

Titanium Exhaust Systems: Enhancing Performance and Reducing Weight

The exhaust system plays a crucial role in a vehicle’s performance, affecting everything from engine power and torque to sound and emissions. Titanium exhaust systems offer a compelling combination of lightweight construction, high strength, and corrosion resistance, making them a popular choice for high-performance applications. By replacing traditional steel exhaust components with titanium equivalents, drivers can reduce the overall weight of the vehicle while also improving exhaust flow and scavenging efficiency. The result is a more responsive engine with increased power and torque output, as well as a distinctive exhaust note that adds to the overall driving experience.

The Dual Purpose of Titanium: Thermal Conductivity in Exhaust Systems

In addition to its lightweight properties, titanium also boasts excellent thermal conductivity, making it an ideal material for high-performance exhaust systems. Unlike steel, which retains heat and can lead to increased under-hood temperatures, titanium quickly dissipates heat away from the exhaust gases, reducing the risk of heat-related engine problems and improving overall reliability. This thermal management capability allows drivers to push their vehicles harder for longer periods without fear of overheating, resulting in more consistent performance on the track or street.

Titanium Lug Bolts: Strength and Lightweight Combined

Lug bolts play a critical role in securing the wheels to the vehicle’s hub assembly, ensuring safe and reliable operation under extreme driving conditions. Titanium lug bolts offer a compelling combination of strength and lightweight construction, making them an ideal choice for high-performance applications. By replacing traditional steel lug bolts with titanium equivalents, drivers can reduce unsprung weight at each corner of the vehicle, improving suspension response and overall handling. Additionally, titanium lug bolts are highly resistant to corrosion, ensuring long-term reliability and durability in harsh operating environments.

Floating Brake Discs: Maximizing Performance while Minimizing Weight

Brake discs are subjected to intense heat and stress during aggressive driving, making them a critical component of any high-performance braking system. Floating brake discs offer several advantages over traditional fixed discs, including reduced unsprung weight, improved heat dissipation, and enhanced resistance to brake fade. Unlike fixed discs, which are rigidly attached to the hub assembly, floating discs are mounted on a separate aluminum hat that allows them to expand and contract independently of the hub. This floating design helps to minimize thermal stress and distortion, resulting in more consistent braking performance under demanding conditions.

Carbon Ceramic Brakes: Revolutionizing Braking Performance

Carbon ceramic brake systems represent the pinnacle of automotive braking technology, offering unmatched performance and durability in a lightweight package. Unlike traditional steel brake discs, which are prone to fade and wear under high-temperature conditions, carbon ceramic discs are virtually immune to heat-related degradation, providing consistent braking performance lap after lap. Additionally, carbon ceramic discs are significantly lighter than their steel counterparts, reducing unsprung weight and improving suspension response. This combination of lightweight construction and exceptional thermal stability makes carbon ceramic brake systems the ideal choice for high-performance driving applications, whether on the track or street.

Forged Aluminum Wheels:

Lightweight Yet Strong: The Appeal of Forged Aluminum Wheels

Forged aluminum wheels offer a compelling combination of lightweight construction, high strength, and durability, making them an ideal choice for high-performance applications. Unlike traditional cast wheels, which are made by pouring molten metal into a mold, forged wheels are created by applying extreme pressure to a solid billet of aluminum, shaping it into the desired wheel design. This forging process results in a wheel that is denser and stronger than its cast counterparts, allowing for reduced material thickness and weight without sacrificing structural integrity. As a result, forged aluminum wheels offer improved acceleration, handling, and braking performance compared to cast wheels, making them a popular choice among performance enthusiasts and professional racers alike.

Manufacturing Process: From Billet to Forged Wheel

The manufacturing process for forged aluminum wheels begins with a solid billet of aluminum alloy, which is heated to a precise temperature and then subjected to intense pressure in a hydraulic press. This forging process compresses the aluminum material, aligning the grain structure and eliminating porosity to create a wheel with superior strength and durability. Once forged, the wheel is machined to its final dimensions, including the spoke design, rim profile, and mounting surface. After machining, the wheel undergoes a series of finishing processes, including heat treatment, shot peening, and surface coating, to enhance its mechanical properties and appearance. The end result is a lightweight, high-performance wheel that is capable of withstanding the rigors of aggressive driving while enhancing the overall performance of the vehicle.

Advantages over Cast Wheels: Strength, Durability, and Weight Reduction

Forged aluminum wheels offer several advantages over traditional cast wheels, including superior strength, durability, and weight reduction. The forging process aligns the grain structure of the aluminum material, creating a wheel that is denser and stronger than its cast counterparts. This increased strength allows for reduced material thickness and weight, resulting in improved acceleration, handling, and braking performance. Additionally, forged wheels are less prone to cracking and deformation under high-stress conditions, making them ideal for aggressive driving applications. The combination of lightweight construction and enhanced durability makes forged aluminum wheels the preferred choice for performance enthusiasts looking to maximize the potential of their vehicles.

Impact on Performance: Improving Acceleration, Handling, and Braking

The reduced weight of forged aluminum wheels has a direct impact on the performance of the vehicle, improving acceleration, handling, and braking in several key areas. By reducing unsprung weight at each corner of the vehicle, forged wheels allow the suspension to react more quickly to changes in road surface, maintaining better tire contact and grip for improved acceleration and cornering performance. Additionally, the reduced rotational inertia of forged wheels improves braking performance, allowing for shorter stopping distances and better pedal feel under hard braking. Overall, the combination of lightweight construction, high strength, and enhanced durability makes forged aluminum wheels an essential upgrade for anyone looking to unleash the full potential of their high-performance vehicle.

Forged Carbon Fiber Wheels:

Pushing the Limits: The Rise of Forged Carbon Fiber Wheels

Carbon fiber wheels represent the pinnacle of lightweight wheel technology, offering unmatched strength, stiffness, and durability in a package that is significantly lighter than traditional aluminum or steel wheels. The use of carbon fiber in automotive applications has grown rapidly in recent years, driven by advances in manufacturing techniques and material science. Forged carbon fiber wheels take this technology to the next level, combining the benefits of carbon fiber’s exceptional properties with the precision and strength of the forging process. The result is a wheel that is lighter, stronger, and more responsive than any other material on the market, making it the ultimate choice for performance enthusiasts and professional racers alike.

Carbon Fiber Manufacturing: Engineering the Future of Automotive Components

Carbon fiber is a composite material consisting of carbon fibers embedded in a matrix resin, typically epoxy or thermoset polymer. The manufacturing process begins with the production of carbon fiber sheets, which are made by spinning carbon fibers into yarns and weaving them into a fabric. These sheets are then impregnated with resin and cured in an autoclave to create a rigid, lightweight composite material. Forged carbon fiber wheels are produced using a similar process, but with the addition of a forging step to shape the material into the desired wheel design. This forging process compresses the carbon fiber layers, aligning the fibers and eliminating voids to create a wheel that is stronger and more durable than traditional carbon fiber components.

Weight Savings: Maximizing Performance without Sacrificing Strength

The primary advantage of forged carbon fiber wheels is their exceptional strength-to-weight ratio, which allows for significant weight savings without sacrificing structural integrity. Compared to traditional aluminum or steel wheels, forged carbon fiber wheels can be up to 50% lighter, reducing unsprung weight at each corner of the vehicle and improving acceleration, handling, and braking performance. This weight reduction not only improves the dynamic capabilities of the vehicle but also reduces rotational inertia, enhancing throttle response and overall agility. Additionally, the stiffness of carbon fiber allows for precise wheel control and feedback, resulting in a more connected driving experience and improved confidence behind the wheel.

Aerodynamics and Heat Dissipation: The Role of Carbon Fiber Wheels in Performance Driving

In addition to their weight-saving benefits, forged carbon fiber wheels offer advantages in aerodynamics and heat dissipation, further enhancing performance on the track or street. The sleek, lightweight design of carbon fiber wheels reduces aerodynamic drag and turbulence, allowing for higher top speeds and improved fuel efficiency. Additionally, the thermal conductivity of carbon fiber helps to dissipate heat generated during braking, reducing the risk of brake fade and ensuring consistent performance under demanding conditions. The combination of lightweight construction, high strength, and advanced thermal management makes forged carbon fiber wheels the ultimate choice for drivers seeking the ultimate in performance and reliability.

Titanium Exhaust Systems:

Unleashing the Roar: The Power of Titanium Exhaust Systems

The exhaust system plays a crucial role in a vehicle’s performance, affecting everything from engine power and torque to sound and emissions. Titanium exhaust systems offer a compelling combination of lightweight construction, high strength, and corrosion resistance, making them a popular choice for high-performance applications. By replacing traditional steel exhaust components with titanium equivalents, drivers can reduce the overall weight of the vehicle while also improving exhaust flow and scavenging efficiency. The result is a more responsive engine with increased power and torque output, as well as a distinctive exhaust note that adds to the overall driving experience.

Lightweight Construction: Reducing Weight and Improving Performance

One of the primary advantages of titanium exhaust systems is their lightweight construction, which allows for significant weight savings compared to traditional steel systems. Titanium is approximately 45% lighter than steel by volume, making it an ideal material for reducing mass in critical areas of the vehicle. By replacing heavy steel exhaust components such as headers, piping, and mufflers with titanium equivalents, drivers can achieve a substantial reduction in overall vehicle weight, resulting in improved acceleration, handling, and fuel efficiency. Additionally, the reduced mass of titanium exhaust components helps to reduce the strain on other vehicle systems, such as the suspension and brakes, further enhancing performance and reliability.

Thermal Conductivity: Managing Heat for Enhanced Engine Efficiency

In addition to its lightweight properties, titanium also boasts excellent thermal conductivity, making it an ideal material for high-performance exhaust systems. Unlike steel, which retains heat and can lead to increased underhood temperatures, titanium quickly dissipates heat away from the exhaust gases, reducing the risk of heat-related engine problems and improving overall reliability. This thermal management capability allows drivers to push their vehicles harder for longer periods without fear of overheating, resulting in more consistent performance on the track or street. Additionally, the improved scavenging efficiency of titanium exhaust systems helps to reduce backpressure and increase engine power and torque output, further enhancing overall performance and drivability.

Sound Enhancement: Tuning the Acoustics for a Thrilling Driving Experience

Another advantage of titanium exhaust systems is their ability to enhance the sound of the engine, providing a more immersive and exhilarating driving experience. Titanium is renowned for its unique acoustic properties, which produce a distinctively crisp and aggressive exhaust note that is prized by performance enthusiasts and automotive enthusiasts alike. By optimizing the design and configuration of the exhaust system, manufacturers can tune the sound of the engine to match the vehicle’s performance characteristics, creating a symphony of power and precision that adds to the overall driving experience. Whether cruising the open road or tearing up the track, the unmistakable sound of a titanium exhaust system is sure to turn heads and leave a lasting impression on all who hear it.

Titanium Lug Bolts:

Bolting Down Performance: The Impact of Titanium Lug Bolts

Lug bolts play a critical role in securing the wheels to the vehicle’s hub assembly, ensuring safe and reliable operation under extreme driving conditions. Titanium lug bolts offer a compelling combination of strength and lightweight construction, making them an ideal choice for high-performance applications. By replacing traditional steel lug bolts with titanium equivalents, drivers can reduce unsprung weight at each corner of the vehicle, improving suspension response and overall handling. Additionally, titanium lug bolts are highly resistant to corrosion, ensuring long-term reliability and durability in harsh operating environments.

Strength-to-Weight Ratio: Maximizing Durability without Adding Mass

One of the key advantages of titanium lug bolts is their exceptional strength-to-weight ratio, which allows for maximum durability without adding unnecessary mass to the vehicle. Titanium is approximately 40% lighter than steel by volume, making it an ideal material for reducing weight in critical areas of the vehicle. By replacing heavy steel lug bolts with titanium equivalents, drivers can achieve a substantial reduction in unsprung weight, resulting in improved acceleration, handling, and braking performance. Additionally, the high tensile strength of titanium ensures that lug bolts can withstand the forces generated during aggressive driving maneuvers, providing peace of mind and confidence behind the wheel.

Corrosion Resistance: Maintaining Performance in Harsh Conditions

Another advantage of titanium lug bolts is their exceptional corrosion resistance, which ensures long-term reliability and durability in harsh operating environments. Unlike steel lug bolts, which are prone to rust and corrosion when exposed to moisture and road salt, titanium lug bolts are highly resistant to corrosion, even in the most challenging conditions. This corrosion resistance helps to maintain the structural integrity of the lug bolts over time, ensuring that they remain tight and secure under all driving conditions. Additionally, the lightweight construction of titanium lug bolts helps to reduce the strain on other vehicle components, such as the suspension and brakes, further enhancing overall performance and reliability.

Precision Engineering: The Science Behind Titanium Lug Bolt Design

The design and engineering of titanium lug bolts are critical to ensuring optimal performance and reliability in high-performance applications. Manufacturers employ advanced techniques such as CNC machining and finite element analysis to optimize the design and configuration of lug bolts for maximum strength, durability, and weight savings. Each lug bolt is carefully engineered to withstand the forces generated during aggressive driving maneuvers, including acceleration, braking, and cornering. Additionally, the threads and seating surfaces of titanium lug bolts are precision-machined to ensure a perfect fit and proper torque retention, minimizing the risk of loosening or failure under extreme conditions. The result is a lightweight, high-performance lug bolt that provides exceptional strength, reliability, and peace of mind for drivers seeking the ultimate in performance and safety.

Floating Brake Discs:

Floating on Air: Understanding Floating Brake Disc Technology

Brake discs are subjected to intense heat and stress during aggressive driving, making them a critical component of any high-performance braking system. Floating brake discs offer several advantages over traditional fixed discs, including reduced unsprung weight, improved heat dissipation, and enhanced resistance to brake fade. Unlike fixed discs, which are rigidly attached to the hub assembly, floating discs are mounted on a separate aluminum hat that allows them to expand and contract independently of the hub. This floating design helps to minimize thermal stress and distortion, resulting in more consistent braking performance under demanding conditions.

Reduced Unsprung Mass: Enhancing Suspension Response and Handling

One of the primary benefits of floating brake discs is their reduced unsprung mass, which improves suspension response and overall handling characteristics. Unsprung mass refers to the weight of components that are not supported by the vehicle’s suspension system, including the wheels, tires, and brake discs. By reducing the weight of the brake discs, floating discs allow the suspension to react more quickly to changes in road surface, maintaining better tire contact and grip for improved acceleration, cornering, and braking performance. Additionally, the reduced rotational inertia of floating discs improves throttle response and overall agility, making the vehicle feel more responsive and dynamic behind the wheel.

Heat Dissipation: Minimizing Brake Fade for Consistent Performance

Another advantage of floating brake discs is their improved heat dissipation, which helps to minimize brake fade and maintain consistent performance under demanding driving conditions. Brake fade occurs when the friction material on the brake pads overheats and becomes less effective at slowing the vehicle, resulting in longer stopping distances and reduced braking performance. Floating discs help to mitigate brake fade by allowing for better ventilation and heat dissipation, preventing the buildup of excessive heat on the braking surfaces. Additionally, the floating design of the discs helps to minimize thermal stress and distortion, ensuring that the braking system operates reliably and consistently lap after lap.

Materials and Construction: Balancing Performance and Durability

Floating brake discs are typically constructed from high-strength materials such as cast iron or carbon ceramic, which offer a balance of performance and durability in high-performance applications. Cast iron discs are favored for their excellent thermal conductivity and resistance to heat fade, making them ideal for aggressive street driving and occasional track use. Carbon ceramic discs offer even greater performance and durability, with superior heat resistance and reduced weight compared to cast iron. However, carbon ceramic discs are more expensive and require careful maintenance to ensure long-term reliability and performance. Regardless of the material chosen, the floating design of the discs helps to maximize performance and minimize brake fade, providing drivers with the confidence to push their vehicles to the limit without fear of overheating or brake failure.

Carbon Ceramic Brake Systems:

Braking Beyond Limits: The Advantages of Carbon Ceramic Brake Systems

Carbon ceramic brake systems represent the pinnacle of automotive braking technology, offering unmatched performance and durability in a lightweight package. Unlike traditional steel brake discs, which are prone to fade and wear under high-temperature conditions, carbon ceramic discs are virtually immune to heat-related degradation, providing consistent braking performance lap after lap. Additionally, carbon ceramic discs are significantly lighter than their steel counterparts, reducing unsprung weight and improving suspension response. This combination of lightweight construction and exceptional thermal stability makes carbon ceramic brake systems the ideal choice for high-performance driving applications, whether on the track or street.

Lightweight Construction: Reducing Rotating Mass for Improved Performance

One of the primary advantages of carbon ceramic brake systems is their lightweight construction, which reduces rotating mass and improves overall vehicle performance. Carbon ceramic discs are approximately 50% lighter than traditional steel discs, resulting in reduced unsprung weight and improved suspension response. This weight reduction not only improves the dynamic capabilities of the vehicle but also reduces rotational inertia, enhancing throttle response and overall agility. Additionally, the lightweight nature of carbon ceramic discs helps to reduce wear and tear on other vehicle components, such as the suspension and drivetrain, further enhancing overall performance and reliability.

Thermal Stability: Resisting Brake Fade under Extreme Conditions

Another advantage of carbon ceramic brake systems is their exceptional thermal stability, which helps to resist brake fade and maintain consistent performance under extreme driving conditions. Brake fade occurs when the friction material on the brake pads overheats and becomes less effective at slowing the vehicle, resulting in longer stopping distances and reduced braking performance. Carbon ceramic discs are highly resistant to heat fade, thanks to their superior thermal conductivity and heat dissipation properties. Additionally, the lightweight nature of carbon ceramic discs helps to reduce thermal stress and distortion, ensuring that the braking system operates reliably and consistently lap after lap. Whether on the track or street, carbon ceramic brake systems provide drivers with the confidence to push their vehicles to the limit without fear of brake failure or performance degradation.

Conclusion:

Transforming your high-performance car or truck into a true powerhouse requires meticulous attention to detail and a willingness to embrace innovation. By incorporating lightweight components such as forged aluminum and carbon fiber wheels, titanium exhaust systems, lug bolts, floating brake discs, and carbon ceramic brake systems, you can unlock new levels of speed, agility, and overall performance. Whether you’re tearing up the track or cruising the open road, these enhancements will elevate your driving experience to unparalleled heights. So, rev up your engine, hit the road, and unleash the beast within your machine.