Carbon fiber is a revolutionary material that has transformed numerous industries, including aerospace, automotive, and of course, motorsports. At its core, carbon fiber is composed of thin strands of carbon atoms, typically woven together into sheets or fabric. These carbon strands are incredibly strong, boasting a tensile strength higher than steel, yet they are significantly lighter in weight.

One of the most remarkable properties of carbon fiber is its exceptional strength-to-weight ratio. Pound for pound, carbon fiber is several times stronger than steel or aluminum, making it an ideal material for applications where weight reduction is critical without compromising structural integrity.

Carbon fiber is also highly resistant to fatigue, corrosion, and temperature extremes, making it well-suited for the demanding conditions encountered in motorsports. Additionally, it can be molded into complex shapes with relative ease, allowing for intricate designs that optimize aerodynamics and performance.

Furthermore, carbon fiber exhibits excellent stiffness and rigidity, providing precise control over chassis flex and aerodynamic stability. This stiffness translates to improved responsiveness and driver feedback, enhancing overall handling characteristics on the track.

In summary, carbon fiber’s unique combination of strength, lightness, durability, and versatility has established it as the material of choice for high-performance applications in motorsports, where every advantage counts in the pursuit of victory.

The Evolution of Carbon Fiber in Motorsports

- Historical Background: When and How Carbon Fiber Started to be Used in Motorsports:

Carbon fiber’s journey into motorsports began in the late 1960s and early 1970s. Initially, its adoption was limited due to high costs and the relatively primitive state of carbon fiber technology. However, its exceptional properties soon caught the attention of engineers and designers seeking ways to gain a competitive edge in racing.

One of the earliest instances of carbon fiber’s use in motorsports dates back to the 1970s, when Formula 1 teams began experimenting with carbon fiber components. McLaren’s founder, Bruce McLaren, is often credited with pioneering the use of carbon fiber in Formula 1, introducing the material to the sport in the early 1980s.

The groundbreaking McLaren MP4/1, introduced in 1981, was the first Formula 1 car to feature a carbon fiber monocoque chassis. This innovative design significantly reduced the car’s weight while providing unparalleled strength and rigidity. The success of the MP4/1 demonstrated the transformative potential of carbon fiber in motorsports, prompting other teams to follow suit.

As carbon fiber technology continued to advance, its applications in motorsports expanded beyond Formula 1 to encompass other racing disciplines such as endurance racing, touring car racing, and rallying. Today, carbon fiber is ubiquitous in motorsports, utilized in everything from chassis and bodywork to suspension components and interior fittings.

- Milestones in the Development of Carbon Fiber Technology for Racing Applications:

The development of carbon fiber technology for racing applications has been marked by several key milestones:

- 1970s: Early experiments with carbon fiber composites in Formula 1, primarily focusing on components like body panels and aerodynamic elements.

- 1981: Introduction of the McLaren MP4/1, the first Formula 1 car with a carbon fiber monocoque chassis, revolutionizing chassis design in motorsports.

- 1980s-1990s: Ongoing advancements in carbon fiber manufacturing processes, resulting in improved strength, stiffness, and cost-effectiveness.

- 1992: The Williams FW14B becomes the first Formula 1 car to win a World Championship with a fully carbon fiber chassis, solidifying carbon fiber’s dominance in the sport.

- 2000s-Present: Continued refinement of carbon fiber technology, including the development of advanced composite materials, automated manufacturing techniques, and simulation tools for optimizing carbon fiber structures.

- These milestones represent significant leaps forward in the application of carbon fiber technology in motorsports, contributing to the ongoing evolution of race car design and performance.

- Impact on Performance and Safety:

The introduction of carbon fiber technology has had a profound impact on both the performance and safety of race cars:

- Performance: Carbon fiber’s exceptional strength-to-weight ratio has enabled race car designers to create lighter, stiffer, and more aerodynamically efficient vehicles. This translates to improved acceleration, top speed, cornering ability, and fuel efficiency, giving drivers a competitive edge on the track.

- Safety: In addition to enhancing performance, carbon fiber has significantly improved safety standards in motorsports. The use of carbon fiber monocoque chassis has greatly enhanced driver protection in the event of a crash, dispersing impact forces more effectively and reducing the risk of injury. Moreover, carbon fiber’s durability and resistance to fatigue ensure that safety structures maintain their integrity throughout the rigors of racing.

Overall, carbon fiber technology has revolutionized motorsports, elevating both performance and safety standards to unprecedented levels and reshaping the landscape of competitive racing.

Advantages of Carbon Fiber in Motorsports

- Lightweight Construction:

Carbon fiber’s low weight is one of its most significant advantages in motorsports, directly contributing to enhanced speed and agility on the track. Unlike traditional materials such as steel or aluminum, carbon fiber offers exceptional strength at a fraction of the weight. This reduction in mass results in several performance benefits:

- Acceleration: With less weight to propel, vehicles constructed with carbon fiber components can accelerate more rapidly, reaching higher speeds in shorter amounts of time. This is particularly advantageous in motorsports events where quick acceleration is crucial, such as drag racing or sprint competitions.

- Agility and Handling: The reduced weight of carbon fiber components improves a vehicle’s agility and handling characteristics. With less inertia to overcome, cars can change direction more swiftly, navigate tight corners with greater precision, and maintain better overall balance through complex maneuvers. This agility translates to improved lap times and a competitive edge on the race track.

- Braking and Cornering: Lighter vehicles experience reduced momentum during braking and cornering maneuvers, allowing for shorter braking distances and quicker changes in direction. This results in more responsive and predictable handling, enabling drivers to push the limits of performance with confidence.

In summary, carbon fiber’s lightweight construction enhances a race car’s speed, agility, and overall performance, making it a preferred choice for motorsports applications.

- Strength and Durability:

Carbon fiber boasts a superior strength-to-weight ratio compared to traditional materials, making it an ideal choice for demanding motorsports environments. This exceptional strength and durability offer several advantages:

- Structural Integrity: Despite its lightweight nature, carbon fiber exhibits remarkable structural strength, capable of withstanding significant forces without deformation or failure. This strength ensures that critical components, such as chassis, roll cages, and suspension elements, maintain their integrity under the extreme stresses encountered during racing.

- Impact Resistance: In the event of a collision or impact, carbon fiber’s inherent toughness disperses energy across the composite structure, minimizing damage and reducing the risk of injury to the driver. This enhanced impact resistance is particularly crucial in motorsports, where crashes are a potential hazard of high-speed competition.

- Longevity: Carbon fiber components are highly resistant to fatigue, corrosion, and environmental degradation, ensuring long-term durability and reliability. This longevity minimizes maintenance requirements and downtime, allowing teams to focus on racing rather than repairs.

Overall, carbon fiber’s strength and durability make it a preferred material for critical components in motorsports, providing both performance benefits and enhanced safety for drivers.

- Customizability and Versatility:

One of the key advantages of carbon fiber is its ability to be precisely engineered and customized to meet specific racing needs. This customizability and versatility offer several benefits:

- Tailored Performance: Carbon fiber parts can be designed and manufactured to exact specifications, allowing for precise tuning of performance characteristics such as stiffness, flexibility, and aerodynamics. This customization enables teams to optimize their vehicles for different tracks, weather conditions, and racing strategies, maximizing competitiveness on the race track.

- Complex Shapes and Designs: Carbon fiber’s molding capabilities allow for the creation of complex shapes and intricate designs that would be impractical or impossible with traditional materials. This flexibility in design facilitates innovative solutions to engineering challenges, such as streamlined aerodynamic profiles, lightweight structural reinforcements, and integrated cooling ducts.

- Weight Distribution: Carbon fiber components can be strategically positioned within a vehicle to optimize weight distribution and balance, improving overall handling and stability. By adjusting the placement of carbon fiber parts, teams can fine-tune the vehicle’s center of gravity, reducing understeer, oversteer, and other handling imbalances.

Applications of Carbon Fiber in Motorsports

- Body Panels and Aerodynamics:

Carbon fiber is extensively used in motorsports to create lightweight and aerodynamically efficient body panels, wings, and diffusers, offering several advantages:

- Weight Reduction: Body panels manufactured from carbon fiber are significantly lighter than their metal counterparts, reducing overall vehicle weight and improving performance. This weight savings translates to faster acceleration, better handling, and increased fuel efficiency on the race track.

- Aerodynamic Performance: Carbon fiber’s ability to be molded into complex shapes allows for the creation of streamlined body panels that optimize airflow around the vehicle. Wings and diffusers constructed from carbon fiber can be precisely designed to generate downforce, enhancing traction and stability at high speeds. This improved aerodynamic performance contributes to faster lap times and better overall competitiveness in motorsports.

- Durability and Impact Resistance: Carbon fiber body panels offer enhanced durability and impact resistance compared to traditional materials like fiberglass or plastic. This resilience ensures that bodywork can withstand the rigors of racing, including debris strikes, minor collisions, and trackside hazards, minimizing downtime and repair costs for racing teams.

In summary, carbon fiber body panels and aerodynamic components play a crucial role in enhancing performance, agility, and safety on the race track, making them indispensable in competitive motorsports.

- Chassis and Structural Components:

Carbon fiber is widely employed in motorsports to reinforce chassis and structural components while simultaneously reducing overall weight. In addition to these applications, carbon-based materials such as carbon-carbon (C/C) and carbon-ceramic brakes, along with carbon fiber wheels, further augment performance and safety in motorsports:

- Carbon-Carbon (C/C) and Carbon-Ceramic Brakes:

- These advanced braking systems utilize carbon-based materials for their exceptional thermal stability and performance under extreme operating conditions. Carbon-carbon brakes, composed of carbon fibers embedded in a carbon matrix, offer superior heat dissipation and resistance to fade during prolonged braking, making them well-suited for high-speed racing applications. Similarly, carbon-ceramic brakes, which incorporate carbon fibers within a ceramic matrix, provide excellent stopping power while reducing unsprung weight compared to traditional steel brakes. The use of carbon-based brake systems enhances braking performance, reduces brake fade, and improves overall reliability, crucial factors in motorsports where precise control and consistency are paramount.

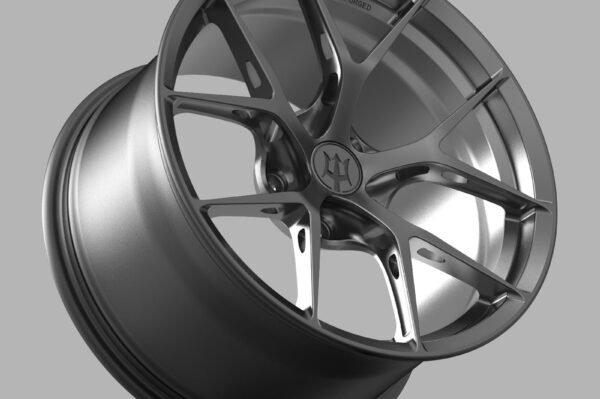

- Carbon Fiber Wheels:

- Carbon fiber wheels represent another innovation in lightweight, high-performance materials for motorsports. Constructed from layers of carbon fiber fabric impregnated with resin and cured under high pressure and temperature, carbon fiber wheels offer significant weight savings compared to conventional aluminum wheels. This reduction in unsprung mass improves suspension response, enhances road-holding capabilities, and reduces rotational inertia, resulting in quicker acceleration and sharper handling. Additionally, carbon fiber wheels exhibit greater stiffness and strength than their metal counterparts, reducing wheel deflection under load and providing more consistent performance on the race track. The use of carbon fiber wheels not only enhances performance but also contributes to fuel efficiency and tire longevity, making them an increasingly popular choice among racing teams seeking a competitive edge.

In summary, the integration of carbon-based materials such as carbon-carbon, carbon-ceramic brakes, and carbon fiber wheels into chassis and structural components elevates performance, reliability, and safety standards in motorsports, underscoring the continual pursuit of innovation and excellence in race car

- Interior Components:

Carbon fiber is utilized in motorsports for lightweight interior components such as seats, dashboard panels, and steering wheels, offering several advantages:

- Weight Reduction: Interior components made from carbon fiber are significantly lighter than their counterparts made from metal or plastic, contributing to overall vehicle weight reduction. This weight savings enhances performance, agility, and fuel efficiency, giving drivers a competitive edge on the track.

- Enhanced Aesthetics and Comfort: Carbon fiber interior components add a touch of sophistication and luxury to race car interiors, reflecting the high-performance nature of motorsports. Carbon fiber seats, for example, offer superior strength and support while reducing fatigue during long races. Dashboard panels and steering wheels crafted from carbon fiber provide a tactile and visually appealing interface for drivers, enhancing comfort and control behind the wheel.

- Customization and Personalization: Carbon fiber interior components can be customized and tailored to meet the specific preferences and requirements of drivers and teams. Whether it’s selecting the weave pattern, finish, or color, carbon fiber offers a high degree of customization options, allowing for personalized interior designs that reflect the identity and branding of the racing team.

Challenges and Future Outlook for Carbon Fiber in Motorsports

Challenges and Limitations:

- Cost: One of the primary challenges associated with the widespread adoption of carbon fiber in motorsports is its relatively high cost compared to traditional materials like steel or aluminum. The cost of raw carbon fiber, along with the specialized equipment and expertise required for manufacturing, contributes to the overall expense of carbon fiber components. Racing teams operating on limited budgets may find it challenging to justify the upfront costs of carbon fiber, despite its performance benefits.

- Manufacturing Complexities: Carbon fiber manufacturing processes are intricate and require precise control over factors such as resin impregnation, curing temperatures, and molding techniques. Achieving consistent quality and structural integrity in carbon fiber parts can be challenging, especially for complex geometries or large-scale production runs. Additionally, the labor-intensive nature of carbon fiber manufacturing can lead to longer lead times and higher production costs, posing logistical challenges for racing teams with tight schedules.

- Repair and Maintenance: While carbon fiber offers exceptional strength and durability, repairing damaged components can be complex and costly. Unlike metals, which can be welded or reshaped, carbon fiber requires specialized techniques such as composite patching or resin infusion to restore structural integrity. Additionally, prolonged exposure to UV radiation or harsh environmental conditions can degrade the resin matrix and compromise the performance of carbon fiber parts over time, necessitating periodic inspections and maintenance.

Emerging Trends and Future Developments:

- Advancements in Manufacturing Technology: Ongoing research and development efforts are focused on advancing carbon fiber manufacturing technology to improve efficiency, reduce costs, and expand design possibilities. Innovations such as automated layup processes, 3D printing of carbon fiber composites, and rapid prototyping techniques hold the potential to streamline production and accelerate the adoption of carbon fiber in motorsports.

- Material Innovations: Researchers are exploring novel carbon fiber compositions, hybrid materials, and advanced resin systems to further enhance the performance and properties of carbon fiber composites. Tailoring the fiber architecture, resin formulations, and manufacturing methods can result in custom-engineered materials optimized for specific racing applications, offering superior strength, stiffness, and durability while mitigating cost and complexity concerns.

- Integration of Sensor Technology: The integration of sensor technology into carbon fiber components allows for real-time monitoring of structural health, performance metrics, and environmental conditions. Smart carbon fiber composites embedded with sensors for strain, temperature, and impact detection enable proactive maintenance, data-driven optimization, and predictive analytics, enhancing safety, reliability, and performance in motorsports.

- Sustainability Initiatives: With increasing emphasis on sustainability and environmental stewardship, there is growing interest in developing eco-friendly alternatives to traditional carbon fiber manufacturing processes. Initiatives such as recycling carbon fiber waste, using bio-based resins, and implementing renewable energy sources for production aim to reduce the carbon footprint of carbon fiber composites and promote sustainable practices within the motorsports industry.

In conclusion, while challenges such as cost, manufacturing complexities, and repair considerations pose hurdles to the widespread adoption of carbon fiber in motorsports, ongoing advancements in technology, materials, and sustainability initiatives hold promise for overcoming these barriers and unlocking new opportunities for innovation and performance enhancement in the future.

Conclusion:

In summary, this article has delved into the multifaceted role of carbon fiber in motorsports, exploring its evolution, applications, advantages, challenges, and future prospects. From its humble beginnings in the 1970s to its pervasive presence in modern racing, carbon fiber has revolutionized the way race cars are designed, built, and driven.

We’ve discussed how carbon fiber’s lightweight construction enhances speed, agility, and fuel efficiency on the track, while its superior strength and durability ensure reliability and safety in high-performance racing environments. Additionally, the integration of carbon-based materials such as carbon ceramic brakes and carbon fiber wheels has further augmented performance and safety standards in motorsports and high-performance cars alike.

Carbon ceramic brakes, utilizing advanced carbon-based materials, offer exceptional braking performance and thermal stability under extreme conditions. They provide consistent stopping power, reduced brake fade, and improved durability compared to traditional steel brakes, making them indispensable in high-speed racing and demanding driving scenarios.

Similarly, carbon fiber wheels have emerged as a game-changer in the realm of high-performance vehicles and motorsports. Constructed from layers of carbon fiber fabric impregnated with resin, carbon fiber wheels offer significant weight savings, enhanced stiffness, and reduced rotational inertia compared to conventional aluminum wheels. These advantages translate to improved acceleration, sharper handling, and better overall performance on the track, setting new benchmarks for excellence in racing engineering.

Despite challenges such as cost, manufacturing complexities, and repair considerations, the importance of carbon fiber in driving innovation and performance in motorsports and high-performance cars cannot be overstated. Its unmatched combination of strength, stiffness, and versatility has enabled racing teams and automotive manufacturers to push the boundaries of speed, precision, and reliability, setting new standards for excellence in competitive racing and enthusiast driving alike.

Looking ahead, the continued evolution of carbon fiber technology, along with advancements in carbon ceramic brakes and carbon fiber wheels, promises even greater advancements in motorsports and high-performance driving. As we embrace these opportunities and overcome challenges, carbon fiber will remain at the forefront of racing and automotive engineering, driving continued innovation, performance, and excitement on the race track and beyond for years to come.